Information about the textile industry

Back to EFFICIENCY FINDER

1 GENERAL INFORMATION

- 1.1 Description, turnover, growth, employment

In 2000 the EU textile and clothing industry actually achieved a turnover of 198 billion euros, involving 114000 companies, who employed about 2.2 million people.

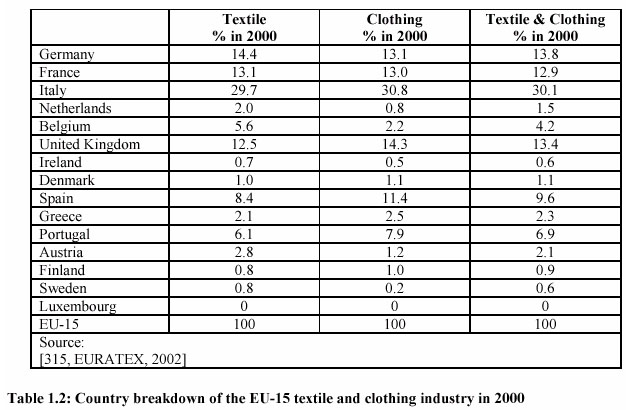

The textile industry’s activities are distributed right across Europe, but mainly concentrated in only a few EU states. Italy is the leading European producer, far ahead of Germany, the UK, France and Spain (in that order). These five countries together account for over 80 % of the Community textile and clothing industry.

- 1.2 Industry structure

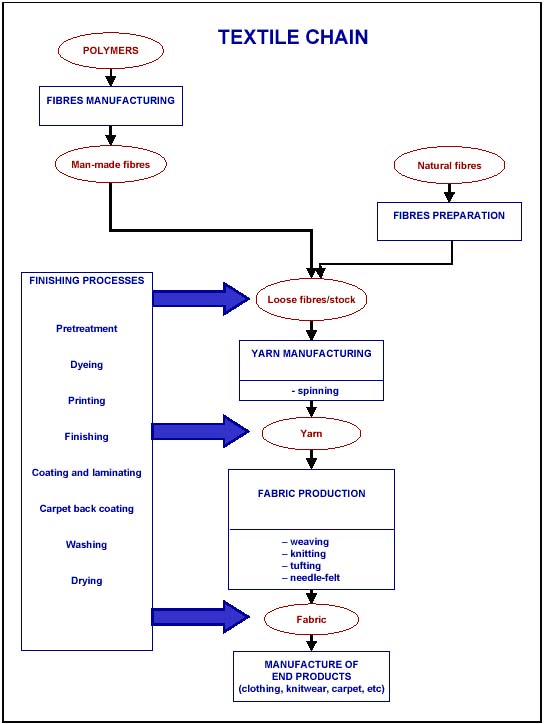

The T/C chain is composed of a wide range of industrial sub-sectors, using the entire range of fibres. European industry is still engaged in all production stages, ranging from raw materials (in particular, the production of man-made fibres), to semi-processed products (in particular, spinning, weaving, knitting, and finishing activities), to the final products (e.g. home textiles, carpets, technical textiles, garments).

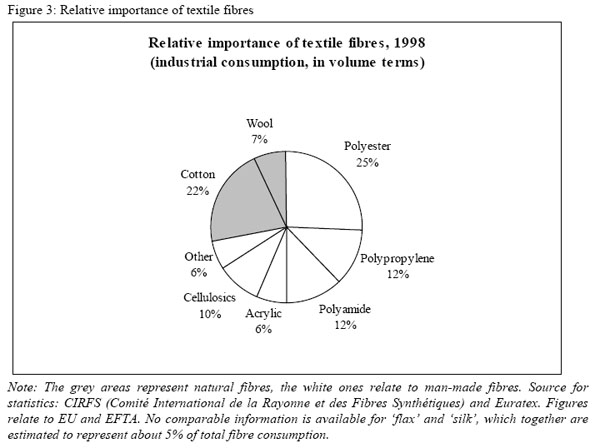

An approximation of the relative importance of individual fibres in Europe’s T/C sector is given in the following graph. In terms of industrial consumption, man-made fibres accounted for about 72% (in 1998, in terms of volume). Cotton is the most important natural fibre.

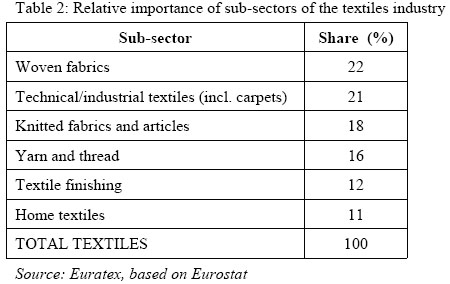

The textile industry is composed of a wide number of sub-sectors, covering the entire production cycle from the production of raw materials (man-made fibres) to semi-processed (yarn, woven and knitted fabrics with their finishing processes) and final products (carpets, home textiles, clothing and industrial use textiles).

The complexity of the sector is also reflected in the difficulty of finding a clear-cut classification system for the different activities involved.

The new nomenclature system (NACE 1997) identifies the following categories:

- yarn and thread

- woven fabric

- textile finishing

- home textiles

- industrial & other textiles (this includes Carpets and Wool Scouring)

- knitted fabrics & articles.

Because of its very specialised nature, carpet manufacturing has always been considered as a stand-alone sector, even though many of the operations carried out are very close to those carried out elsewhere in textile finishing.

2 APPLIED PROCESSES AND TECHNIQUES

The textile chain begins with the production or harvest of raw fibre. The so-called “finishing processes” (i.e. pretreatment, dyeing, printing, finishing and coating, including washing and drying) represent the core of the applied processes and techniques. The “finishing processes” can take place at different stages of the production process (i.e. on fabric, yarn, loose fibre, etc.), the sequence of treatments being very variable and dependent on the requirements of the final user.

- 2.1 Overview of processing techniques and unit operations

“Textile finishing” cannot be defined as a standard sequence of treatments, but rather is a combination of unit processes that can be applied within the production of a textile product, depending on the requirements of the final user. The basic steps in this chain are schematically represented in the following diagram that can not be clearly not exhaustive.

| Process | MJ/kg |

| Single desize | 1.7 |

| Scouring and bleaching | 9.2 |

| Mercerising | 6.9 |

| Jet dyeing of polyester | 20.2 |

| Pad batch dyeng of cotton | 3.7 |

| Finishing (resin) | 12 |

(Literature: Faculty of Chemistry and chemical enineering, University of Maribor: Waste minimisation in the textile industry, Maribor, January 1995)

3 BIBLIOGRAPHY

- European Commission, (2003), “Integrated Pollution Prevention and Control Reference Document on Best Available Techniques for Textile Industry”

- European Commission, (2005), http://europa.eu.int/comm/trade/issues/sectoral/industry/textile/index_en.htm

Back to EFFICIENCY FINDER